CNC (Computer Numerical Control) lathes are automated machine tools that rotate a workpiece against a cutting tool to remove material and produce a desired shape. The process is controlled by a computer, allowing for high precision and repeatability in manufacturing.

Processes Involved in CNC Lathing

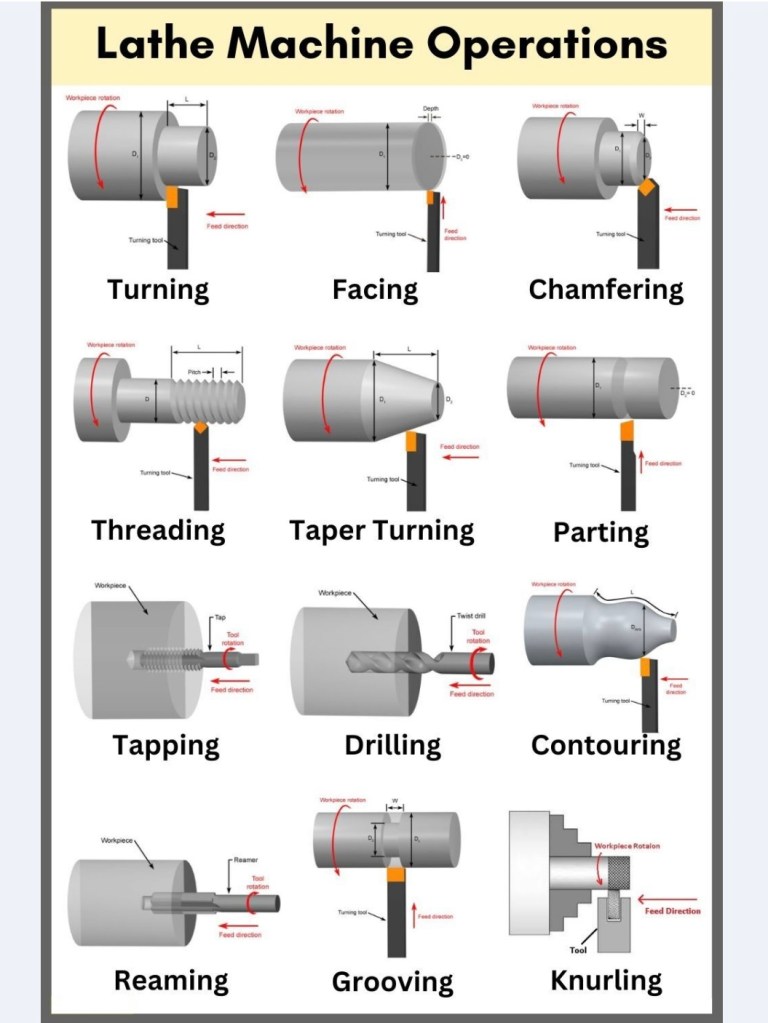

- Turning: The primary operation where the workpiece is rotated, and the cutting tool moves along its length, removing material to achieve the desired diameter and shape.

- Facing: A process for creating a flat surface on the end of the workpiece. The cutting tool moves perpendicular to the axis of rotation.

- Drilling: CNC lathes can also incorporate drilling operations where hole features are created in the workpiece.

- Boring: Enlarging an existing hole with a rotating cutting tool.

- Threading: Creating screw threads on the surface of the workpiece, either internal or external.

- Grooving: Cutting narrow grooves or channels into the workpiece.

- Contour Turning: Producing complex shapes or profiles along the length of the workpiece.

- Parting Off: Cutting the finished part from the remaining material at the end of the operation.

Materials Suitable for CNC Lathes

CNC lathes can work with a variety of materials, including:

- Metals:

- Aluminum

- Steel (carbon, alloy, stainless)

- Copper

- Brass

- Titanium

- Plastics:

- ABS

- Nylon

- Polyethylene

- Polycarbonate

- Composites:

- carbon fiber

- fiberglass

- Others:

- Wood and certain types of ceramic materials can also be processed using CNC lathes with appropriate tooling.

Industries That Utilize CNC Lathes

CNC lathes are widely used across multiple industries, including:

- Aerospace: Manufacturing complex components such as turbine parts, landing gear, and precision fittings.

- Automotive: Producing engine components, shafts, brackets, and other precision parts for vehicles.

- Medical: Creating instruments, surgical tools, and implants where precision is critical.

- Electronics: Making parts for devices such as housing for components, heat sinks, and connectors.

- Energy: Manufacturing components for oil and gas, renewable energy systems, and power generation machinery.

- Heavy Machinery: Producing gears, axles, and various components for industrial equipment.

Products Made with CNC Lathes

Some common products produced using CNC lathes include:

- Shafts and axles

- Bushings and bearings

- Screws, nuts, and bolts

- Gears and sprockets

- Fittings and adapters

- Spindles and rotary bodies

- Medical implants and devices

Summary

CNC lathes are powerful tools in modern manufacturing, providing versatility in processes and materials for a range of industries. The ability to achieve high precision and the capability to automate complex tasks make them indispensable in producing a wide variety of products.

Leave a comment